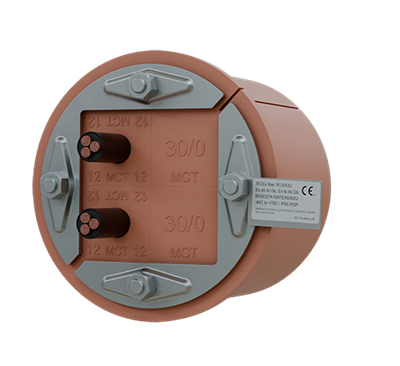

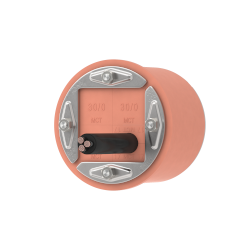

RGP - S Ex

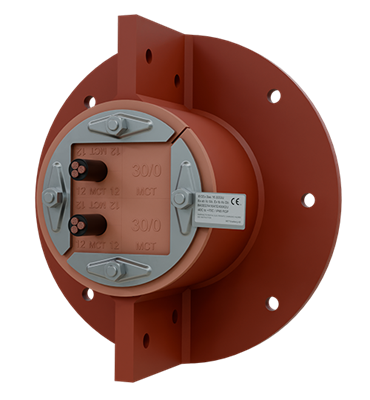

The RGP Ex assembled in a standard sleeve that can be welded or casted to a structure.

See sleeve variations for specific attachment options and sizes.

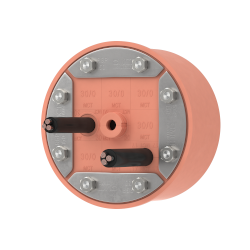

The marking of the equipment and protective system

Group II Category 2GD Ex eb IIC Gb Ex tb IIIC Db Tamb (-40°C to+70°C)

Ex

- Available as both equipment and component

Component:

Component is not intended to be used alone and requires additional consideration when incorporated into other equipment or systems for use in explosive atmospheres (refer to IEC 60079-0)

- Ex system combined with EMC has yellow marking on the front face (see EMC instructions)

- MCT Brattberg RGP Ex system must be installed with supplied sleeve.

Correct and safe installations

To achieve the highest standard of safety, a cable or pipe transit must be installed correctly. As there are many different types of frame – which may be either welded, bolted or glued into position – and insert block, it is essential that installers known when to use the most appropriate installation method.

For more information, please view following instructions, videos or download manuals as PDFs.

PRESSURE-TIGHT INSTALLATION

All contact surfaces between the pipe and the RGP plug must be cleaned carefully prior to installation. Do not use any lubricant on these surfaces. All blocks must be lubricated carefully with MCT Brattberg lubricant. The penetration must not be subjected to pressure for at least 48 hours after installation. This is to allow the pressure to equalise throughout the penetration. It will take more time for the pressure to equalise at temperatures below 20°C.

Note: If the installation is subjected to pressure, all components must be replaced after removal and refitting.

Instruction documents

For more information visit Instructions and manuals

The RGP is available in 12 standard diameters 50, 70, 100, 125, 150, 200, 300 mm, 3", 4", 5", 6", 8" and is packed with MCT insert blocks. The hardware is available in galvanized or stainless steel (316L) and aluminium.

RGP 50 (2")

RGP 70 (2.75") or RGP 3" (76.2mm)

RGP 100 (3.93") or RGP 4" (101.6mm)

RGP 125 (4.92") or RGP 5" (127mm)

RGP 200 (7.87") or RGP 8" (203.2mm)

RGP 150 (5.90") or RGP 6" (152.4mm)

Ex and ATEX requirements are very strict, some Ex Insert blocks may not be approved with certain systems.

Read more about Insert Blocks in general.

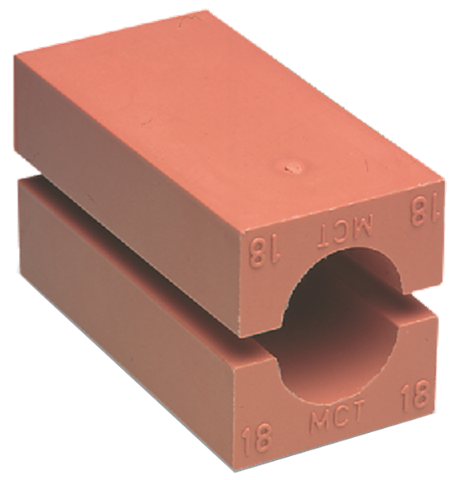

Standard Block Ex

Following standard blocks in the table are approved:

Spare Block Ex

Following Spare blocks in the table are approved:

AddBlock Ex

Following Addblocks in the table are approved:

General

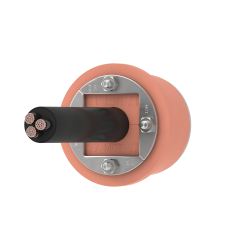

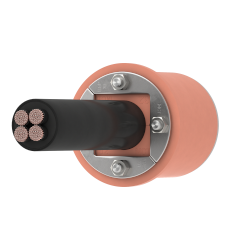

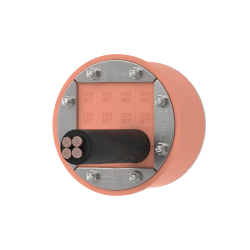

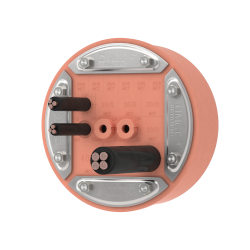

The system consists of a round rubber frame (RGP Ex) and rubber blocks. The RGP Ex system must be installed with a MCT Brattberg sleeve as a kit, and packed with rubber blocks suited for each cable and pipe dimension. The compression bolts are tightened to compress the rubber blocks against cables and pipes to establish a tight seal.

The marking of the equipment and protective system: Group II Category 2GD Ex eb IIC Gb Ex tb IIIC Db Tamb (-40°C to+70°C)

Note: MCT Brattberg RGP Ex system must be installed with supplied sleeve.

Benefits of MCT Brattberg Ex systems

- Ex rated transit for hazardous environments

- Assists cable management

- Seals the penetration against the passage of fire, water, gas, sound and environmental hazards

- Can be combined with special EMC modules and for Grounding and Bounding

- Unlike other brands our system can be dismantled and re-used

- Cable dimension marked on block

- No adaptation of standard blocks needed

For more information visit Certificates

System components

Standard Block

Designed to seal cables and pipes with diameters from 3.5 – 110 mm (0.14-4.33”). Other dimensions can be supplied to order.

See specs and variations for Standard Block

AddBlock

Available in eleven block sizes and 66 cable dimensions.

See specs and variations for AddBlock

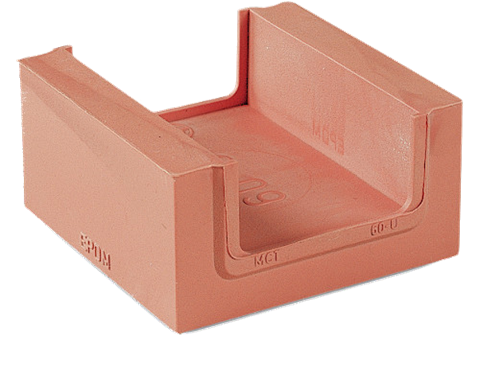

SpareBlock

Unused space in the frame is filled with solid spare blocks.

See specs and variations for SpareBlock

U-Block

Used to enlarge the external dimensions of blocks to the next modular size.

See specs and variations for U-Block

Lubricant

Shall be applied on all Lycron parts sealing surfaces when such demands exist

See specs and variations for Lubricant

CCM - Casting Module

Concrete Casting Module - Knock-Out Plate

See specs and variations for CCM - Casting Module

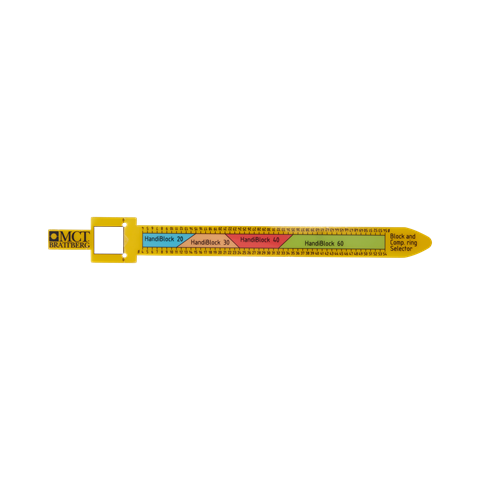

Block Selector

For cable and pipe measurement. Insert blocks, add blocks and HandiBlocks.

See specs and variations for Block Selector

Tweezers

Assist insertion of last block in each row

See specs and variations for Tweezers